Product characteristics

Product characteristics

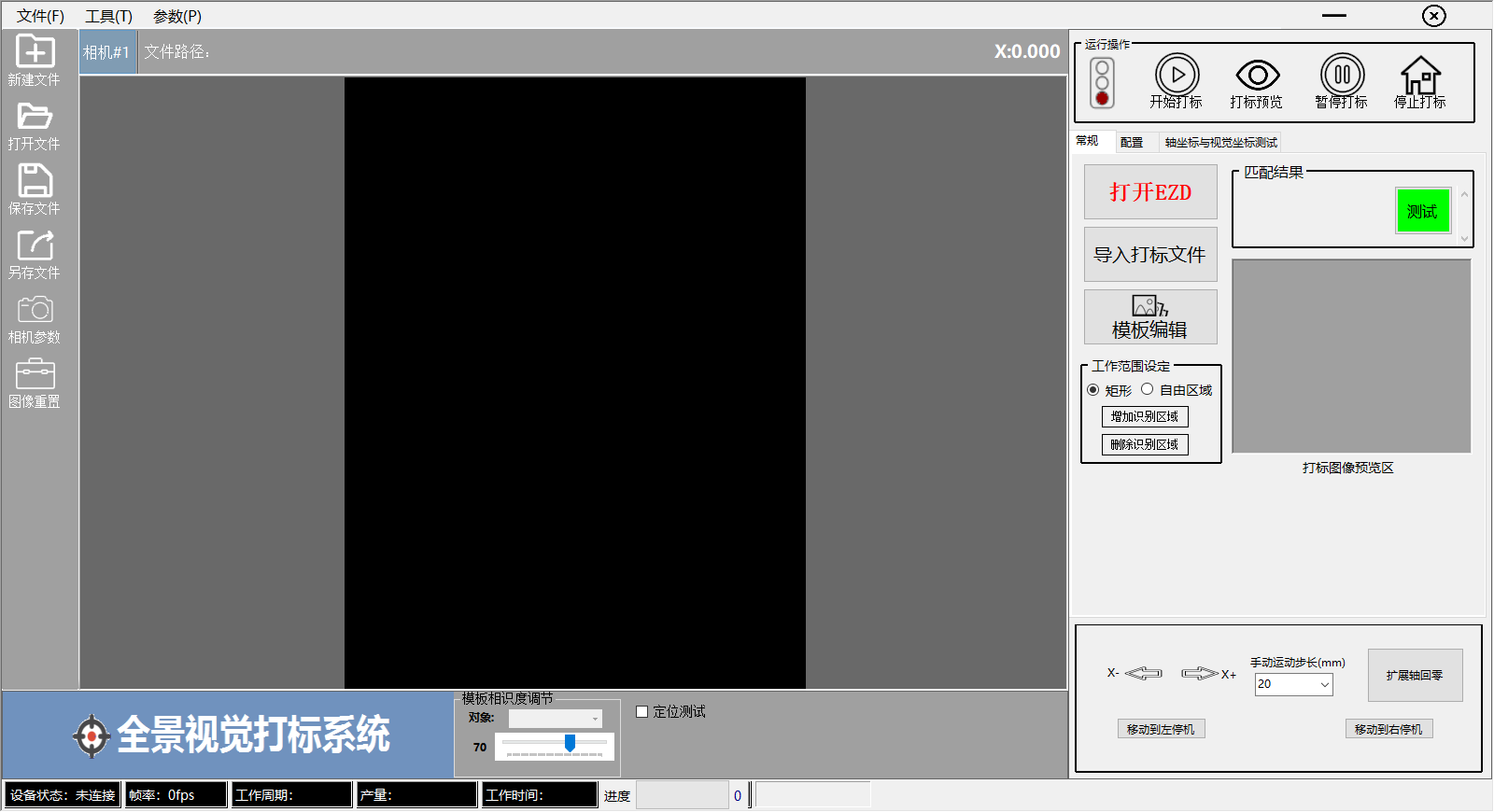

The key automatically calibrates, associating the vision with the laser coordinates

1The distortion calibration function corrects the visual lens to improve the marking precision

2Support multi-product, 360-degree identification, one-time identification of multiple products, according to the platform product automatic classification and marking

3Area tagging, just add tagging area can achieve a single or multiple product tagging

4Products do not need fixed direction, number, software automatic identification to work

5Has 3 marking trajectory planning modes (row first, column first, most recent mode) to improve efficiency and reduce time

6Visual movement anti-weight, identify anti-weight function, to avoid repeated product recognition and repeated marking

7Flexible authorization mode, according to the needs of the authorization, control the use of equipment time

8Support different Axis mode, non-axis, single x-axis, XY-axis, pipeline (fixed distance) , pipeline (sensor)

9

Technical parameters

Technical parameters

| Technical parameters | ||

| Models | VO9-LM | |

| Description of model | Laser marking | |

| Camera model | Hikang camera | |

| Lens focal length | f=8mm/12mm/Other | |

| Shooting area | Other | |

| Identification method | Visual recognition | |

| Number of individual identifications | No restriction | |

| Software support platform | WIN7/WIN10 | |

| Programming style | Draw with the mouse | |

| Calibration method | Automatic calibration | |

Application

Application

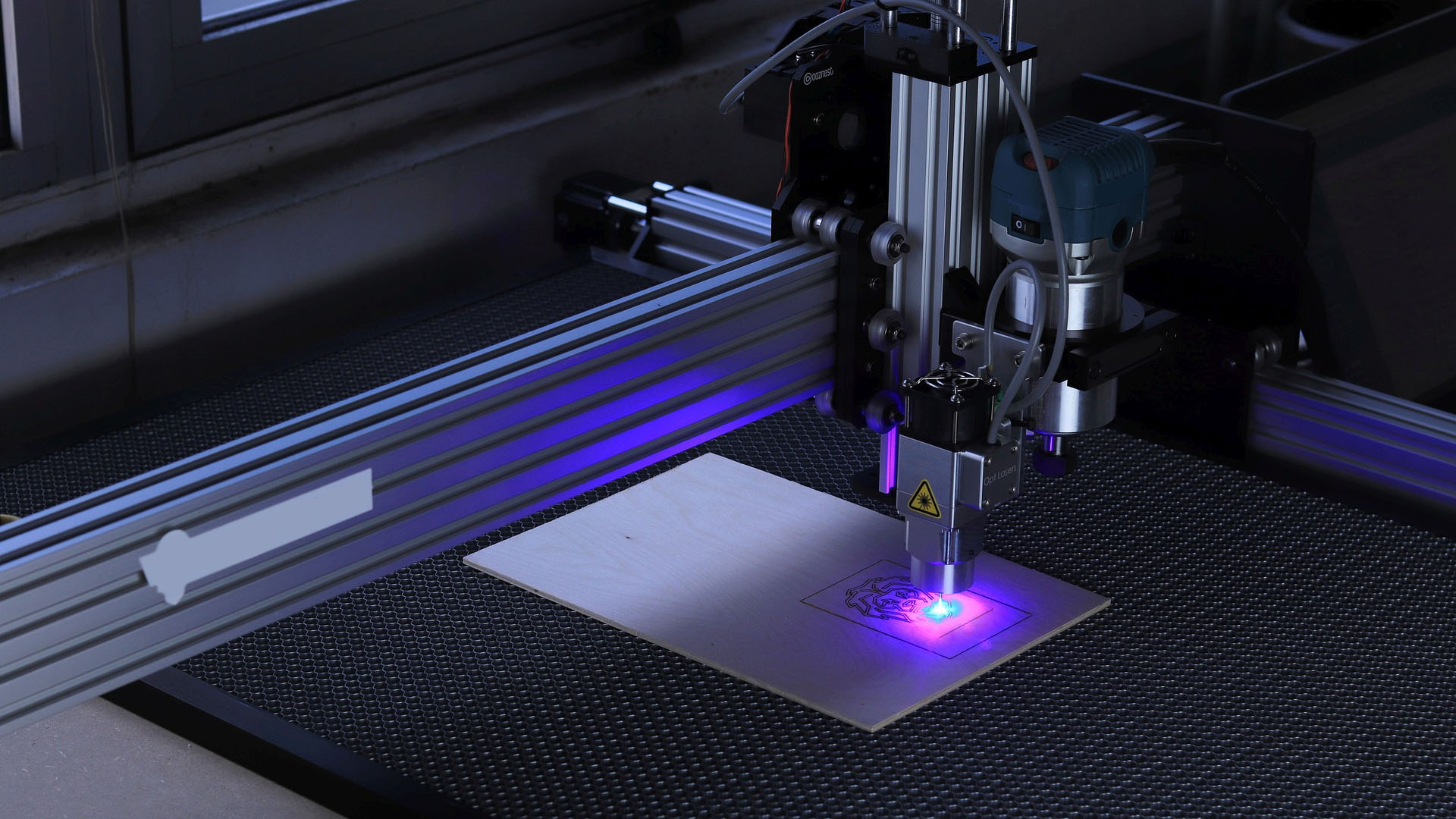

CCD vision pipeline marking machine is suitable for fine machining market, mobile phone laser marking, charger is automatically coded by laser coding, medicine laser coding, cosmetic box laser lettering marking, polymer packaging bottle surface marking, flexible PCB plate automatic identification marking